Three Containers – One Circular System: A New “Food Factory” Brings Sustainable Luxury to the City

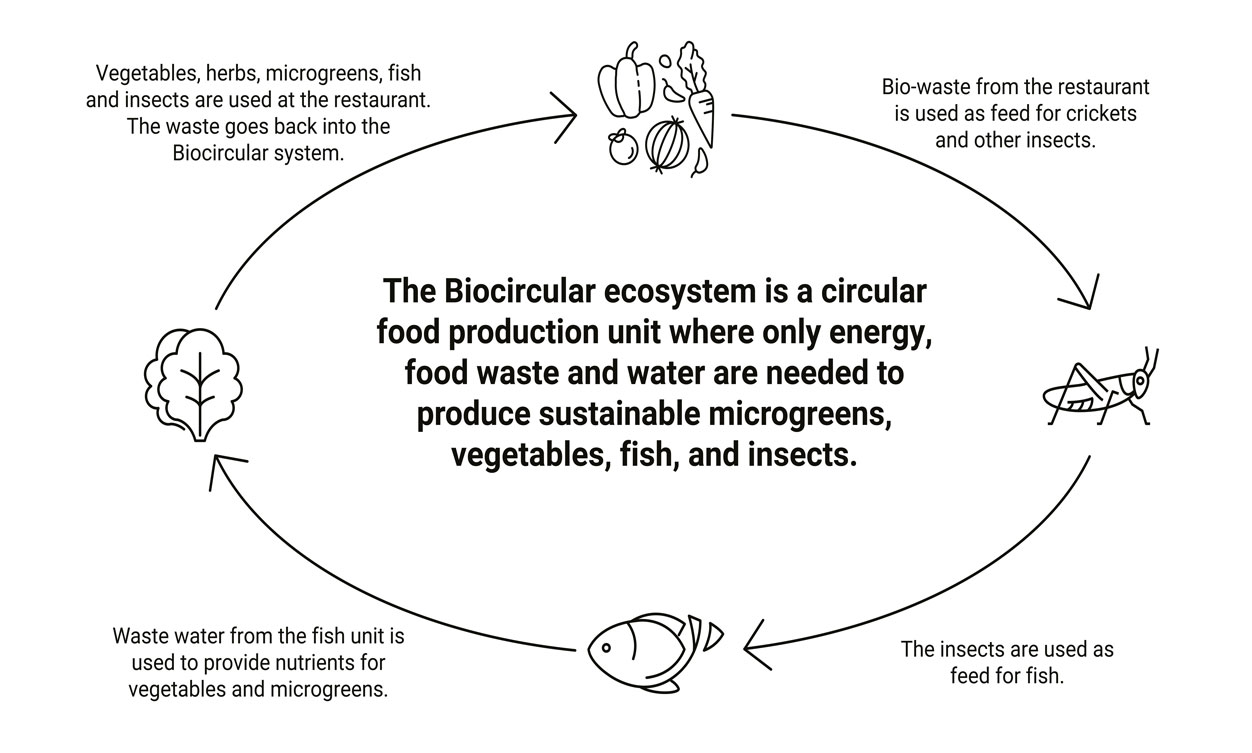

After three years of intensive work, Nordicflexhouse is ready to present the first fully integrated BioPod containers, developed in collaboration with OxyGuard, Bugging Denmark, and Restaurant Alchemist. This is a cohesive ecosystem where fish, vegetables, and insects are cultivated side by side, utilizing each other’s resources in a closed-loop system.

“Our vision has been to prove that high gastronomic quality and circular production can go hand in hand. The container solution creates new opportunities to transform kitchen waste into new ingredients – right where they are needed,” says Anders Thomsen, CEO of Nordicflexhouse ApS and project manager for the initiative.

Three Containers – One Circular System

The three-year development project, supported by GUDP, explored how vegetables, insects, and fish can be cultivated in an integrated container system located on Refshaleøen, just steps from Alchemist’s kitchen.

The cycle begins with the restaurant’s own food waste – such as citrus peels – being converted into insect feed in a repurposed container, which Bugging Denmark has transformed into a fully automated insect farm. The facility can produce more than one ton of mealworms annually, which are used both as food and as sustainable feed for the fish.

“When we replace industrial fish feed with our own mealworms, we significantly reduce the CO₂ footprint and keep production local,” says Jakob Rukov from Bugging Denmark.

The mealworms are then transferred directly to the neighboring container, where OxyGuard has installed a compact recirculating aquaculture system (RAS) in a 40-foot container. During the project period, over 1,000 African catfish (Clarias gariepinus) have been raised with minimal water usage.

“The fish container produces both a liquid and a solid fraction of nutrient-rich sludge – the liquid part is sent directly to the vegetable container, while the solid can be used as fertilizer in open fields,” says Lasse Polke-Pedersen from OxyGuard.

In the third container – the BioPod vegetable container from Nordicflexhouse – more than 40 types of herbs, microgreens, and edible flowers are grown year-round under LED lights, nourished by the recirculated fish water. The harvest is used in the restaurant – and in this way, the entire cycle is connected, enabling a complete circular food factory to operate on just 72 square meters.

Concrete Climate Results

The BioPod containers are highly climate-friendly. A BioPod vegetable container removes about 0.20 kg of CO₂ from the atmosphere per kg of vegetables produced annually. In contrast, traditional vegetable farming emits 3.58 kg of CO₂ per kg of vegetables produced annually. The climate impact of insect production is only 1.22 kg CO₂ per kg of mealworms or crickets – significantly lower than traditional protein sources (for comparison, beef emits around 60 kg CO₂ per kg).

An independent fish container emits 2.85 kg CO₂ per kg of catfish produced annually. Traditional catfish farming emits 5 kg CO₂ per kg annually.

From Waste to Gourmet

Michelin-starred restaurant Alchemist’s role in the project has been to test the BioPod containers in operation, which has led to tangible results on the restaurant’s menu.

“It’s been an exciting journey to be part of. The idea of a circular system where we can use our food waste to create new food aligns with our philosophy. During the project, we’ve harvested over 40 different types of herbs, microgreens, and insects from the BioPod containers, and our test kitchen has experimented with more than 100 preparation methods for the African catfish,” says Rasmus Munk, head chef and co-owner of Alchemist.

Market-Ready Solution

The BioPod containers are CE-marked, fully automated, and come with digital monitoring platforms and manuals, allowing operation in about 8 hours per week. The solution is now ready for the Danish and international markets – with the ambition to see biocircular containers pop up on rooftops and vacant urban spaces around the world.

Read more about the BioPod solution here:

https://www.biopodcontainer.dk/

Press Contact

Nordicflexhouse:

Anders Thomsen +45 52 25 04 93

ant@nordicflexhouse.dk

NordicFlexHouse Design & Innovation Co. (2025 Winner: Scandinavian Business Awards)

NordicFlexHouse has been recognised for its innovative contributions to sustainable construction and digital solutions. Their projects, such as the BioPod container solution for energy-efficient urban farming and mobile healthcare units designed for remote areas, demonstrate their commitment to integrating digital tools like Building Information Modelling (BIM) with sustainable construction practices: NordicFlexHouse Design & Innovation Co. (2025 Winner: Scandinavian Business Awards) – EU Business News

SEAlgaePower

EU project has been granted: SEAlgaePower – Sustainable development of microalgae-based products using waste streams from aquaculture and seafood processing industry as feedstock.

Nordicflexhouse is partner in this project.

The fast-growing aquaculture and seafood processing industry generate large amounts of nutrient-rich wastewaters, posing a high cost for discharge and environmental impact. There is a lack of technologies for valorisation of these wastewaters, while there is an increasing demand for new resources intended for carbon-neutral production of food, material and energy. The ability of microalgae to perform photosynthesis and efficiently convert dissolved nutrients into valuable biomass could contribute to solving this dual problem.

The overall objective of the SEAlgaePower project is to develop innovative technologies where microalgae can clean currently wasted nutrient-rich water from the aquaculture (like our BioPod fish container) and seafood processing industry while simultaneously producing biomass for development of novel ingredients in a sustainable way.

Top sustainable solution 2023

Nordicflexhouse has been nominated as a finalist for The SDG Tech Awards, the ultimate celebration of sustainable technologies, taking place on the 4th of December at Industriens Hus.

Huzhou business visit

The Huzhou government come to Copenhagen 7th of July with the purpose of establishing business collaboration projects together. The business collaboration projects will focus on Eco village and Greenlab in Huzhou together with Danish and Nordic companies. Focus areas are green buildings, water and waste treatment, vertical farming, sustainable food production and smart community solutions.

The 7th of July we will have a workshop with Huzhou government and Vice Mayor of Huzhou. Also a China business delegation will attend the workshop together with Danish companies and organizations.

The goal of the workshop is to have an agreed understanding of the two demonstration projects and to have the opportunity to meet the Danish companies that will be part of the two demonstration projects. The purpose of meeting is also to have person to person discussions and reflections.

More information about the workshop and the two demonstration projects: See here

If you are interested to join the workshop, please send email to Anders Thomsen: ant@nordicflexhouse.dk

NISS Campus – a new entry point to China

Possible design of the NISS Campus

China is stepping up efforts to reach the zero carbon targets, a development visible across all industries including building and construction. This opens up great possibilities for Nordic companies with environmentally smart solutions and high quality products in the Chinese market. Nordic Innovation and Sustainability Shanghai (NISS) is a new development set up to support this, by founded by the Danish entrepreneur Simon Lichtenberg. The NISS Campus will be China’s first net zero campus, located in the attractive Hongqiao district of Shanghai close to the airport and high speed train station. The construction work will start in 2022 to build 60,000 m2 of office, R&D and showroom space.

NISS is looking for Nordic partners who wish to take part in this development, as a unique opportunity to use one of the most modern developments in China as a showcase for leading Nordic technology. Your materials and solutions can be used in the construction and we can help you enter the Chinese market through our on the ground platform. NISS collaborates with a number of partners, such as Sino Nordic Innovation cluster, for market entry to China.

NISS Campus in short:

– A platform for zero carbon, green tech and Nordic culture collaboration to China, supported by Governments and business community

– A unique network with fast access to insight and partners for green development projects in China

– A practical showcase of use of Nordic technology in China – the largest green building market in the world

For more information contact Anders Thomsen, Nordicflexhouse (ant@nordicflexhouse.dk; 52250493)

See www.nisscampus.com, or the attached presentation.

Sino Nordic Smart city with the heart conference

Nordicflexhouse arrange together with Nordic Edge a conference in Beijing the 26-27 May 2021. Because of COVID19 it will be a webinar for International participants. Chinese participants will join the conference in Beijing.

Enclosed save the date information.

See the conference program here with the possibility to register to the conference:

Nordic Edge Asia – Nordic Edge

For more information, please contact Anders Thomsen; ant@nordicflexhouse.dk; mobile: +45 52250493

Value added food innovation.

VIDA is an EU funded project working with green farming solutions. One of these projects are the Biopod container solution: www.biopodcontainer.dk

A webinar takes place 18-19 May. Please see the program and register to webinar here: